Sk-15 IR Carbon Fiber Filament Lamp For Electric Heater Parts

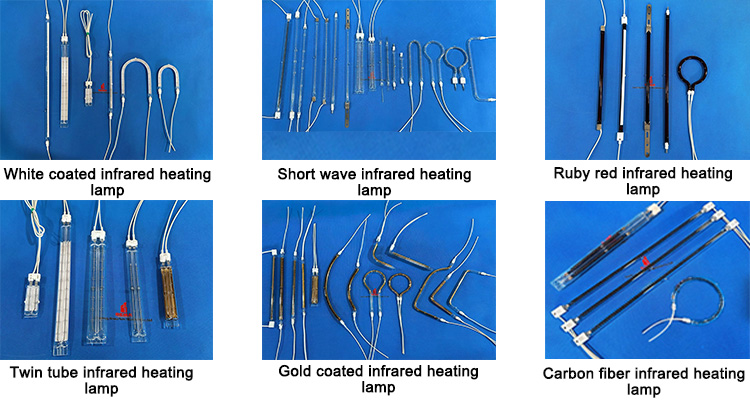

The biggest difference between Short Wave ir lamp and the standard short-wave quartz lamp is that it uses ruby quartz tubes, which blocks the output of UV and a large amount of visible light, eliminating glare at the application site and improving production safety.

Input Voltage:230V

Input Wattage:1100W

Working Lifetime:5000+ Hours

IR Distance: 0.9-1.8μm.

OEM/ODM:Can be customized according to customer requirements.

- REMA

- China

- 5-10 days

- 200000 Pieces

- Information

REMA 230v 1100w SK-15 Ruby Red Infrared Carbon Fiber Filament Lamp Electric Heater Parts For Heating and Drying

The top quality of filament can let the lamp keep long time life

1.High efficiency.

2.Economical to run.

3.Have a fast response switching on and off timeEffectively transmit and focus heat on materials

High purity99.99% qurtz glass tube

1.Is totally transparent at lR radiation.

2.quartz is used in halogen bulbs because it can withstand high temperatures. Quartz also ensures against heat shock.

Name: | IR carbon fiber lamp | Voltage : | 24-600V |

Wattage | 100-5000W | Heated length : | 100-1400mm |

Response time: | 1-2 s | Wavelength: | 0.9-1.8 um |

Tube diameter: | 8-12mm | Filament temperature: | 1100-2900℃ |

Application:Automotive manufacturing, textiles, plastics, spraying, paper making, printing, inks, adhesives, solar photovoltaics, etc | |||

1. High-efficiency energy source

High-efficiency heat sources that convert and emit over 85% of the input power to infrared. Lamp-based heat irradiation produces high-quality infrared irrespective of the ambient temperature .

2.Non-contact heating.

Heats objects without direct, physical contact.

3.High controllability due to nature of “light”

Light energy can be controlled optically using mirrors to focus and disperse the light, and hence heat, to “direct” the heat to the target. This provides high-level control over the heated area .

4.Clean heat source.

Objects are heated in any environment, whether exposed to the atmosphere or in a vacuum, alleviating concerns about harming the object or the environment.

5.Quick on/off response.

Radiated energy rises and falls almost simultaneously as the switch is turned on/off due to the use of filaments with low heat capacity.

6.Long life and constant energy emission

Halogen-cycle lamp for long-life design of 5,000 hours.

Furthermore, the lamps maintain almost constant energy emission until the end of the rated life.

7.Heating in vacuum.

Proven track record as a heat source with high reliability in vacuum equipment.

OEM/ODM

If the parameter is not suitable for you. Welcome to contact us .REMA Design an infrared lamp for the unique you !

| How to customized ? Pls provide this informations: | |||

| 1.Voltage: | 220V、380V、... | 2.Wattage: | 1000w、2000w、.. |

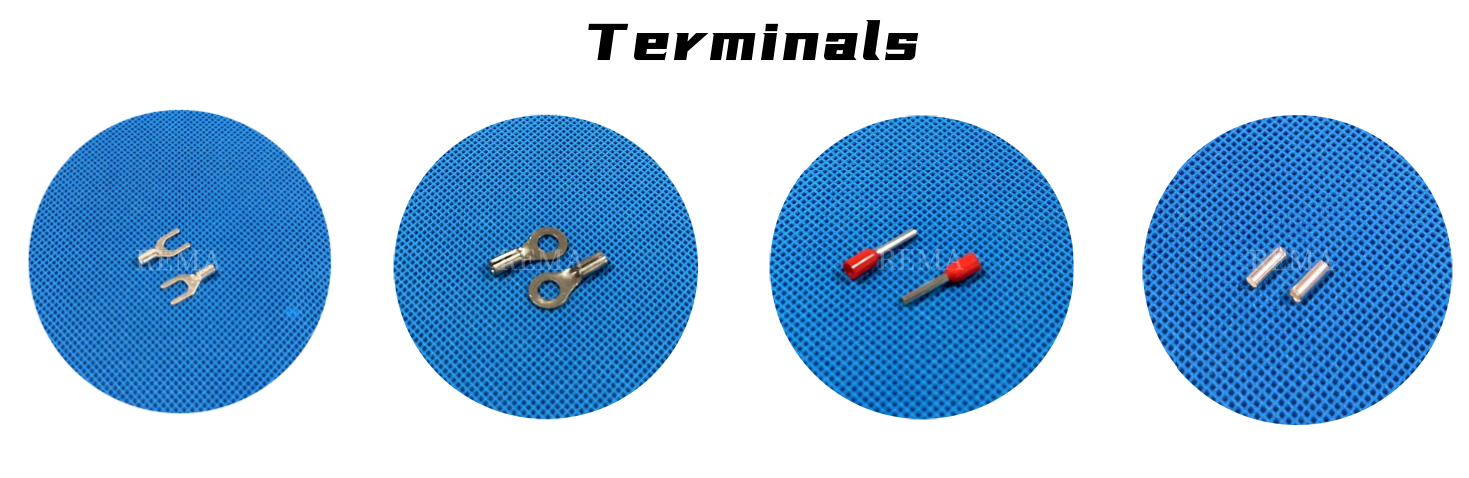

| 3.Total length: | **mm | 4.Wire length: | 500MM、..... |

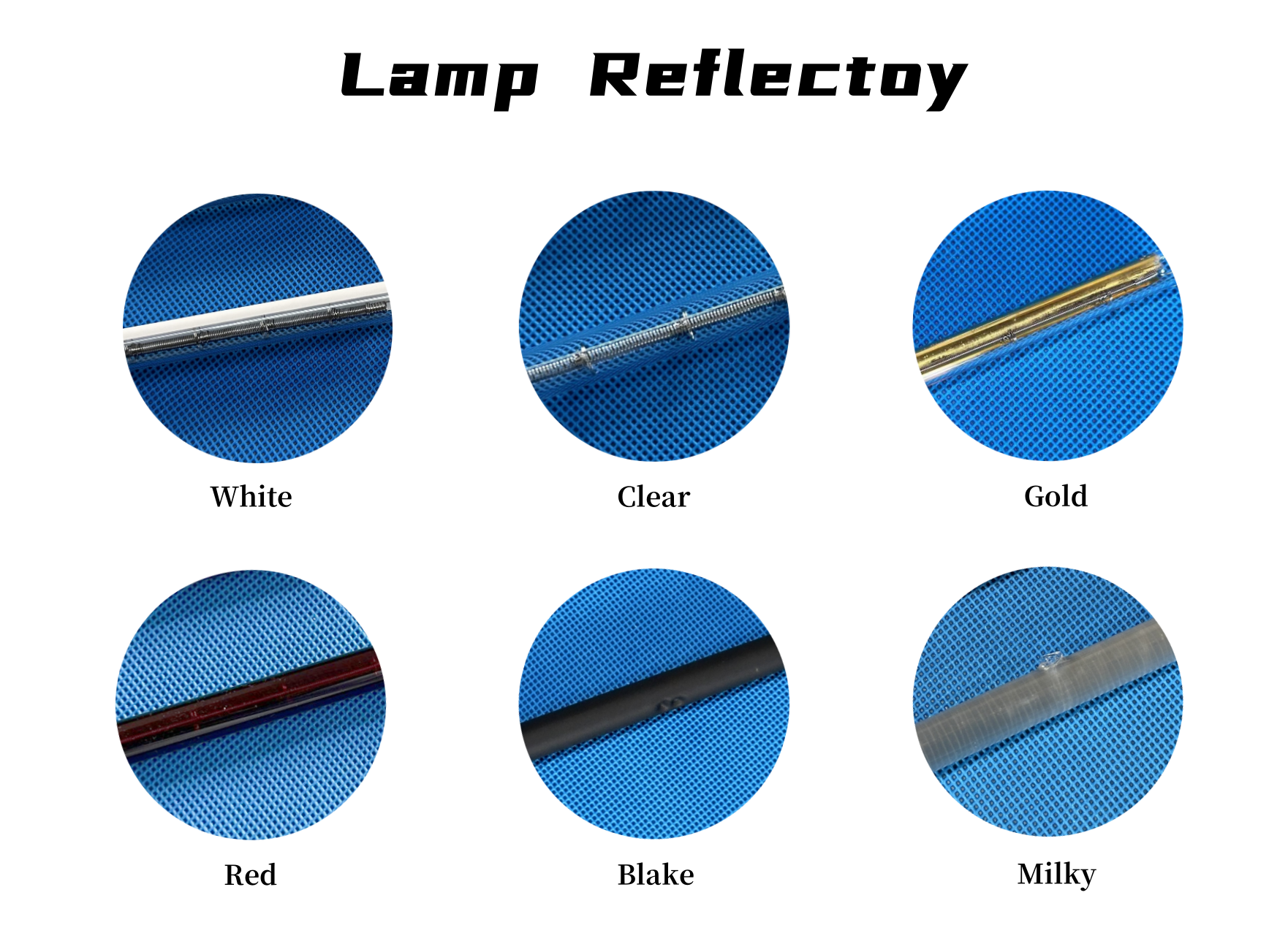

| 5.Coated or not.What color coating? | Gold/ White/ Clear/Black | 6.Base: | SK15、R7s、..... |

| Or you can directly send us the photos and drawings. | |||

Custom Lamp Base LOGO

REMA uses laser printing LOGO. Make the LOGO more clear , durable and not easy to disappear by friction.

AFTER-SALE GUARANTEE

MAINTENANCE AND CARE

– Regular cleaning: During use, dust, oil and other impurities may accumulate on the surface of quartz heating lamp, affecting its heating effect and service life.

Therefore, it is necessary to clean the quartz heating lamp regularly, and you can use a clean soft cloth or paper towel to gently wipe the surface.

– Check the circuit: Regularly check whether the connection circuit of the quartz heating lamp is normal, whether there is looseness, short circuit, etc.,

to ensure its normal operation.

– Avoid collision: Quartz glass is relatively fragile. Avoid collision or falling during installation and use to avoid damage to the quartz heating lamp.