Infrared Halogen Lamp For Vacuum Coating System

Halogen lamp has a quick response time: 1-2 Seconds, And heats up quickly,Strong radiation,Great penetration. The irradiated object can be heated from a deeper level.

Input Voltage:110V

Input Wattage:750W

Working Lifetime:5000+ Hours

IR Distance:1-2μm.

OEM/ODM:Can be customized according to customer requirements.

- REMA

- China

- 5-10 days

- 200000 Pieces

- Information

REMA 110v 750w Shortwave Clear Single Tube Tungsten Filament Near Molybdenum Rod Infrared Lamp For Vacuum Coating System

Name: | Infrared Halogen Vacuum Coating lamp | Voltage : | 24-600V |

Wattage | 100-5000W | Heated length : | 100-1500mm |

Response time: | 1-2 s | Wavelength: | 1-2um |

Tube diameter: | 8-12mm | Filament temperature: | 1100-2900℃ |

Application:Automotive manufacturing, textiles, plastics, spraying, paper making, printing, inks, adhesives, solar photovoltaics, etc | |||

Halogen heaters for vacuum use

These Halogen lamp use parts that do not emit impure gases or particles, even when used in a vacuum, to produce clean heating. The clip base uses a nickel plate that can be freely bent or twisted, cut,and mounted with screws to suit the physical mounting location.

Customized Service

No suitable product for you? Welcome to contact us .REMA Design an infrared lamp for the unique you !

With thousands of specification IR lamps,infrared short wave lamp (SW), infrared medium wave lamp (MW),

Infrared fast medium wave lamp (Fast MW) and infrared special lamp, more than 30 years processing experience,

Skilled and experienced technical team, Make our products more excellent , Welcome to customize it according to your requirements !

Glass drying:

Drying silkscreen print on car windows, cutting laminated glass or coating mirrors -many glass processing activities require heating. REMA Infrared can be perfectly adjusted to the specific process, such as Silkscreen printing on glass, Vacuum coating on glass, Silver mirror production line and Manufacture of laminated glass.

.By using REMA infrared emitters and heating equipment, you will witness these preponderances:

Fast heating greatly shortening the line size, saving space

Fast radiatorresponse, easy to control, 1-2 seconds pre-operating

Matching with the absorption of glass, high heating efficiencytime

Heat more evenly, good coating effect

Stable performance,long life time, no maintenance need

Lamp Base

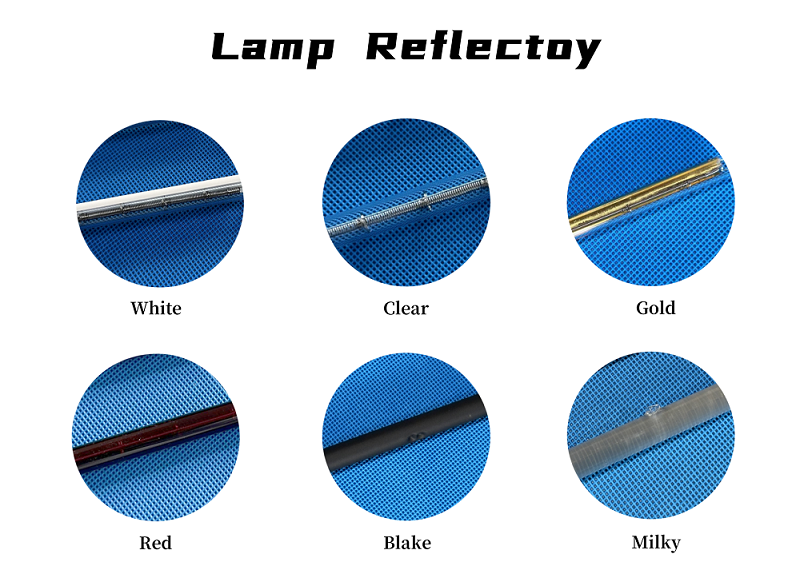

Reflective coating of the lamp

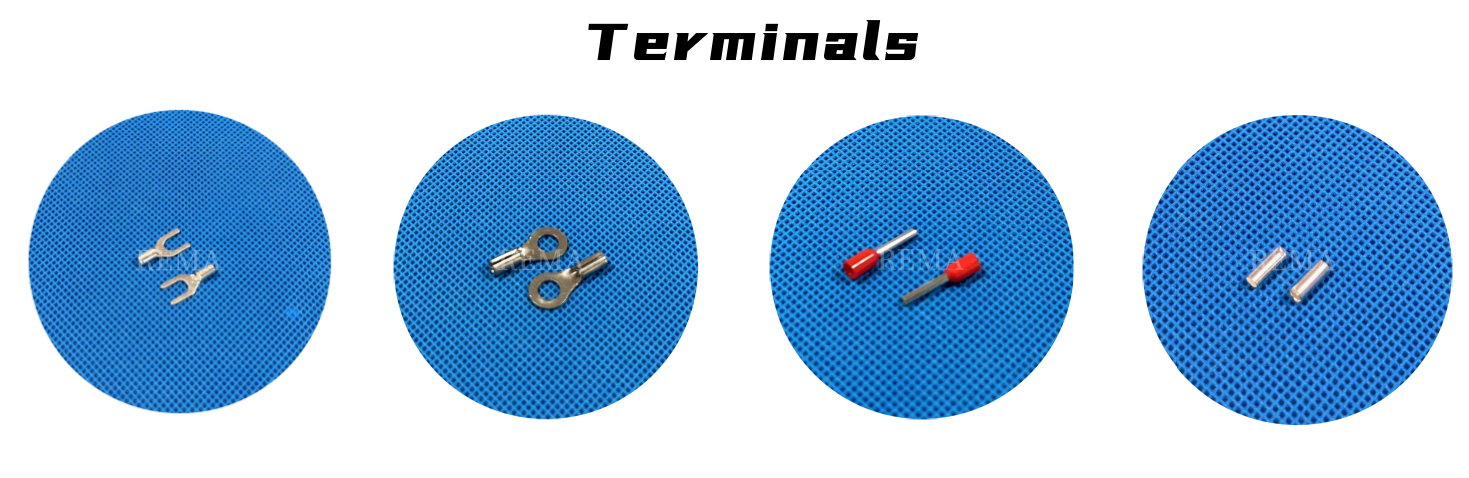

Terminal

According to our experience, the characteristics of the irradiated objects (heating /drying/ physiotherapy/ disinfection) are different, and the spectrum energy absorption caused by infrared radiation are also different.

When selecting infrared radiation products ,we recommend that customers pay special attention to the following data in order to select suitable products:

Metal---1~2 μm (Short wave) High speed printing --- 1~2 um (Short wave )

Resin---2~4 μm (Middle wave) High-grade matte paint drying room---3~50 μm (Long wave)

Glass---2-4 μm (Middle wave) Water system dying---2-4 ym (Middle wave)

High speed printing --- 1~2 ym (Short wave ) High-grade matte paint drying room---3~50 μm (Long wave)

Physical rehabilitative treatment (lmported bulb)---1.35um (standing A)

---2.2um (standing B ).

According to our experience, the characteristics of the irradiated objects (heating /drying/ physiotherapy/ disinfection) are different, and the spectrum energy absorption caused by infrared radiation are also different.

When selecting infrared radiation products ,we recommend that customers pay special attention to the following data in order to select suitable products:

Metal---1~2 μm (Short wave) High speed printing --- 1~2 um (Short wave )

Resin---2~4 μm (Middle wave) High-grade matte paint drying room---3~50 μm (Long wave)

Glass---2-4 μm (Middle wave) Water system dying---2-4 ym (Middle wave)

High speed printing --- 1~2 ym (Short wave ) High-grade matte paint drying room---3~50 μm (Long wave)

Physical rehabilitative treatment (lmported bulb)---1.35um (standing A)

---2.2um (standing B ).