Clear Halogen Lamp Quartz For Paint Drying Curing

halogen lamp quartz has a quick response time: 1-2 Seconds, And heats up quickly,Strong radiation,Great penetration. The irradiated object can be heated from a deeper level.

Input Voltage:220V

Input Wattage:1250W

Working Lifetime:5000+ Hours

IR Distance:1-2μm.

OEM/ODM:Can be customized according to customer requirements.

- REMA

- China

- 5-10 days

- 200000 Pieces

- Information

REMA 220v 1000w Paint Drying Curing halogen lamp For Vacuum Forming Machine

High temperature resistance, corrosion resistance, good thermo-chemical stability, long service life, high insulation strength.

Clean heating process , no pollution.

Direct heat transfer , little loss in air saving 60% energy.

Out-from-within heating , improving the producing quality dramatically .

Easy to design, manufacture and install, economical and safe.

Wide range of matching heating , making it possible for heating many kinds of products.

Name: | Clear halogen lamp | Voltage : | 24-600V |

Wattage | 100-5000W | Heated length : | 100-1500mm |

Response time: | 1-2 s | Wavelength: | 1.1-1.8 um |

Tube diameter: | 8-12mm | Filament temperature: | 1100-2900℃ |

Application:Automotive manufacturing, textiles, plastics, spraying, paper making, printing, inks, adhesives, solar photovoltaics, etc | |||

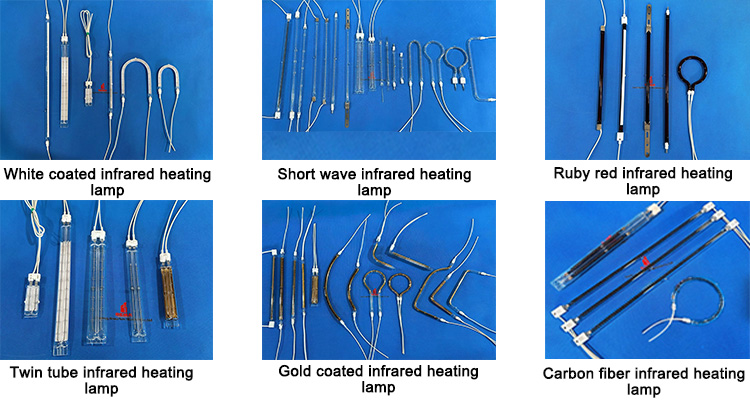

Short wave halogen lamp quartz are used in various industrial applications:

Plastic welding.

Semiconductor material activation.

Car seat leather dehumidification and wrinkle removal.

Non-woven fabric heating and drying.

Drying process in paper mill.

Battery cell welding.

Metal sheet heat treatment.

Ink drying and curing.

Drying Wood:

REMA drying equipment used in the production of wooden furniture

Application:drying wood on the water-based paint

Features:

Easy open and turn-off,saving energy.

High efficiency in the field by uniform heating.

achieve the perfect surface quality.

Saving space.

Easily fixed into existing production lines.

Since attention is paid to the environmental protection, the woodprocessingindustry began to usewater-based paint, Therefore.customers are trying to use water-based paint,

but a series ofproblemsappear: traditional solvents will be volatile after heating,but water-based paint will not, it is so difficult tobe dried thus hinderthe next coating process.

Byusing REMA infrared radiation: two meterslong with 12kW lamps, customers are endowed with the courage of throwing away the traditionalgas convection oven,

needing 20 meters production line and costing about 30 minutes for complete drying Practice proves that REMA drying equipment increases productivity,saves energy&space.

OEM/ODM

If the parameter is not suitable for you. Welcome to contact us .REMA Design an infrared lamp for the unique you !

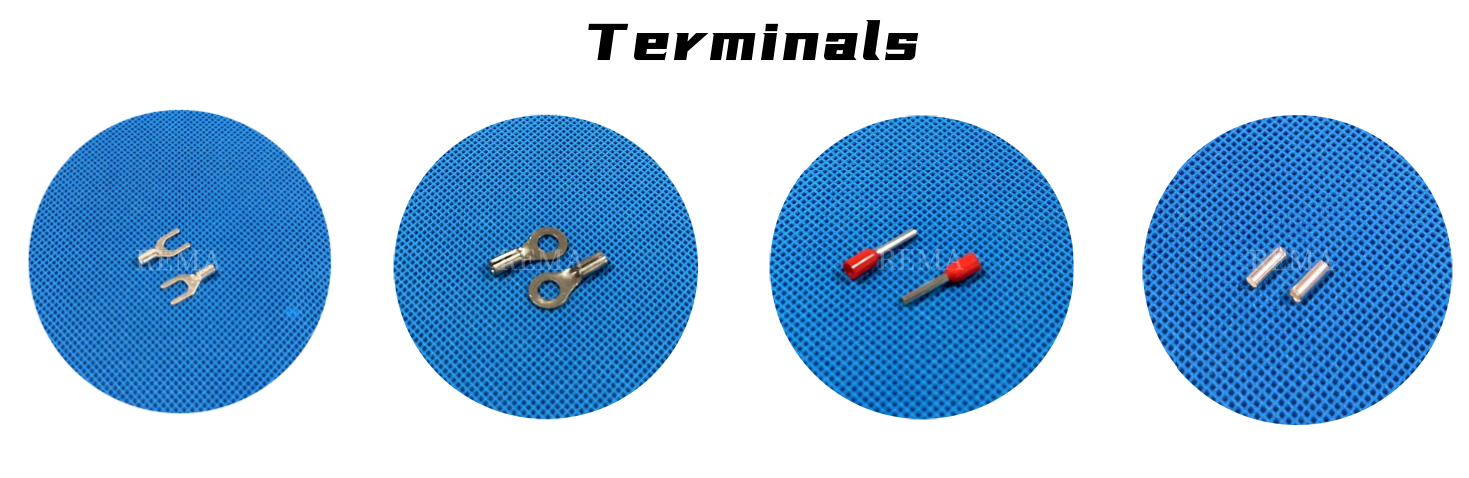

| How to customized ? Pls provide this informations: | |||

| 1.Voltage: | 220V、380V、... | 2.Wattage: | 1000w、2000w、.. |

| 3.Total length: | **mm | 4.Wire length: | 500MM、..... |

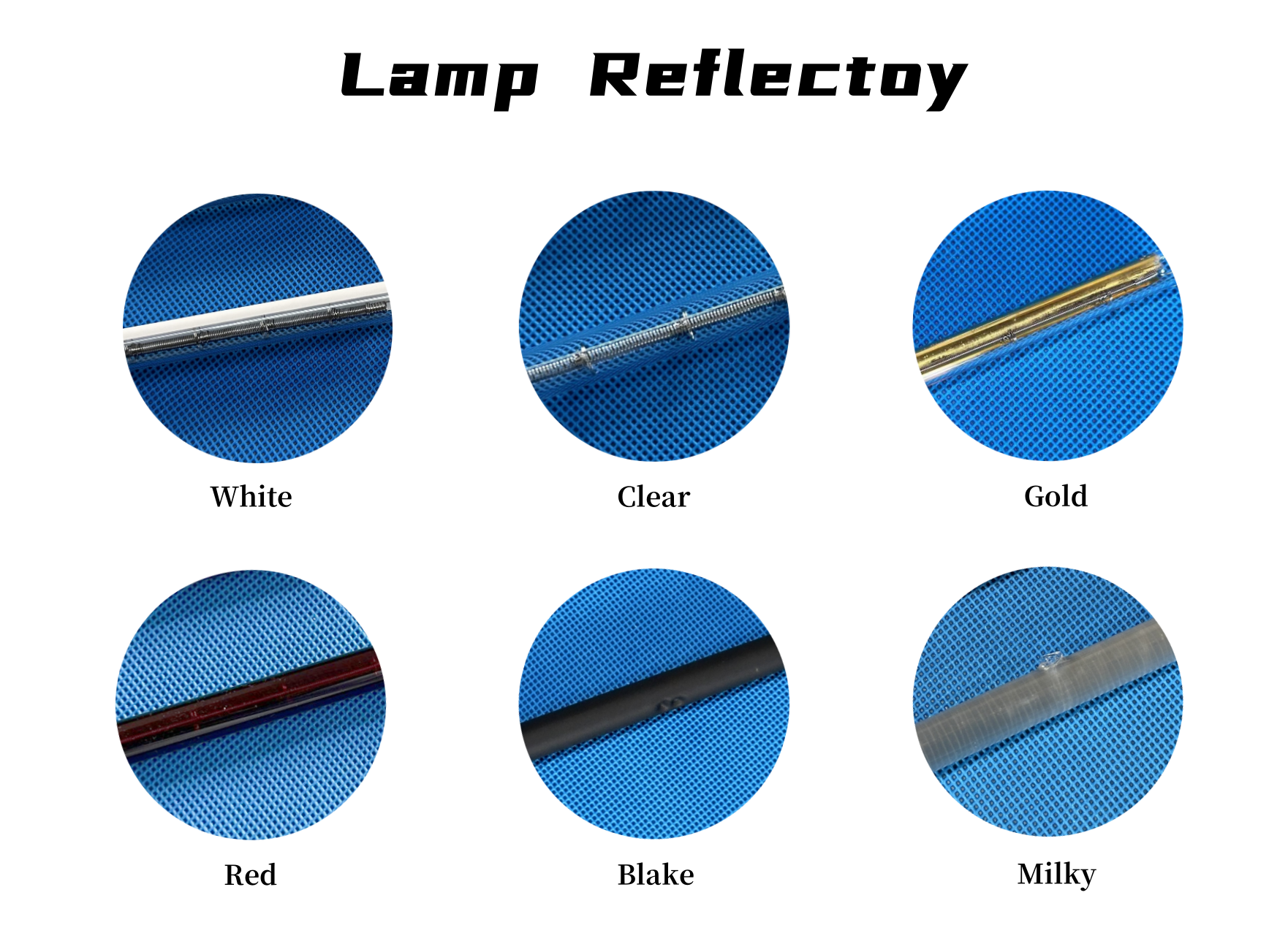

| 5.Coated or not.What color coating? | Gold/ White/ Clear/Black | 6.Base: | SK15、R7s、..... |

| Or you can directly send us the photos and drawings. | |||

Custom Lamp Base LOGO

REMA uses laser printing LOGO. Make the LOGO more clear , durable and not easy to disappear by friction.

AFTER-SALE GUARANTEE

Before we proceed with the shipment, we will send you a customized product video and packaging for your confirmation.

After shipment, we will update the logistics information and tracking number in time

Professional customer service.

Complete package.

Damaged replacement & After-sales service.

We promise that we can change or refund the products if there is any quality problem.