U Shape Half White Ruby Red Quartz Infrared Heating Lamp Element

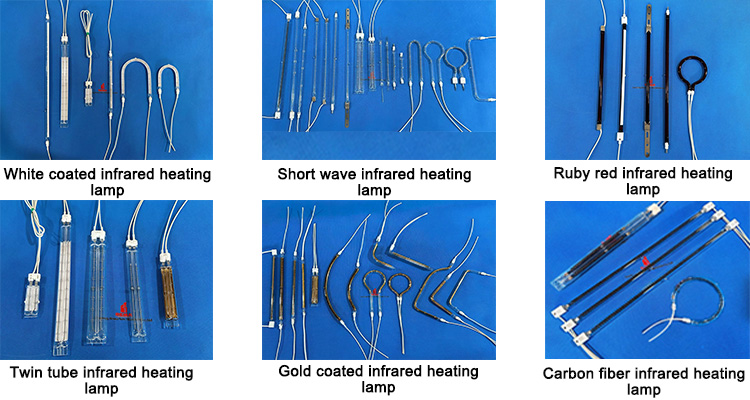

The biggest difference between Quartz Infrared Element and the standard short-wave quartz lamp is that it uses ruby quartz tubes, which blocks the output of UV and a large amount of visible light, eliminating glare at the application site and improving production safety.

Input Voltage:220V

Input Wattage:1000W

Working Lifetime:5000+ Hours

IR Distance: 0.9-1.8μm.

OEM/ODM:Can be customized according to customer requirements.

- REMA

- China

- 5-10 days

- 200000 Pieces

- Information

REMA 220v 1000w U Shape Half White Ruby Red Quartz Infrared Heating Lamp Element

The top quality of filament can let the lamp keep long time life

1.High efficiency.

2.Economical to run.

3.Have a fast response switching on and off timeEffectively transmit and focus heat on materials

High purity99.99% qurtz glass tube

1.Is totally transparent at lR radiation.

2.quartz is used in halogen bulbs because it can withstand high temperatures. Quartz alsoensures against heat shock.

Name: | Half White Ruby Quartz Infrared lamp | Voltage : | 24-600V |

Wattage | 100-5000W | Heated length : | 100-1400mm |

Response time: | 1-2 s | Wavelength: | 0.9-1.8 um |

Tube diameter: | 8-12mm | Filament temperature: | 1100-2900℃ |

Application:Automotive manufacturing, textiles, plastics, spraying, paper making, printing, inks, adhesives, solar photovoltaics, etc | |||

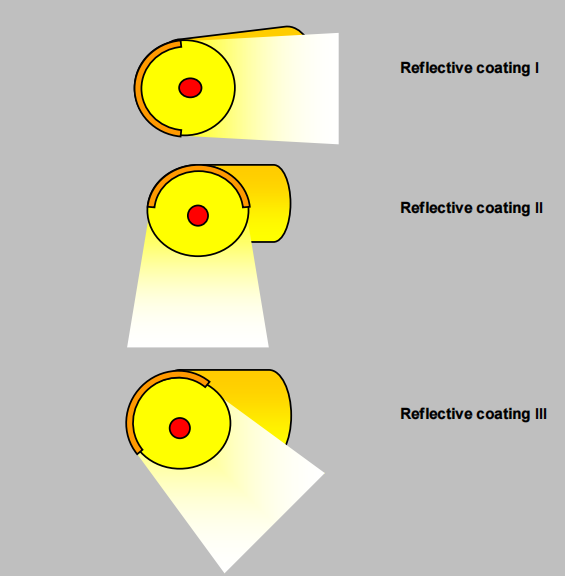

Halogen heaters with reflective film

A white coating is applied to the rear surface of the lamp which increases the efficiency and the energy

emitted from the front of the lamp, and eliminates the optical components, such as the reflective mirror,

reducing the cost. It also helps suppress the increase in temperature of surfaces on the side of the reflective film.

Infrared emitters can be individually formed to match the requirements of the finishing process. So, heat is targeted to where it is needed, e.g.

Joining, welding or riveting of plastic parts

Forming or bending of tubes

Drawing of glass or plastic fibers

Special shaped quatz glass infrared emitters are popularly applied to the automotive interior and exterior production ines, heating applications like below:

1.Infrared joining and welding for plastics components

2.Thermoforming of car carpet and ceiling

3.Vacuum laminating

4.Deburring of plastic

5.Edge wrapping

6.Activating adhesives

7.PET performs heating in stretch blow moulding machines.

OEM/ODM

If the parameter is not suitable for you. Welcome to contact us .REMA Design an infrared lamp for the unique you !

| How to customized ? Pls provide this informations: | |||

| 1.Voltage: | 220V、380V、... | 2.Wattage: | 1000w、2000w、.. |

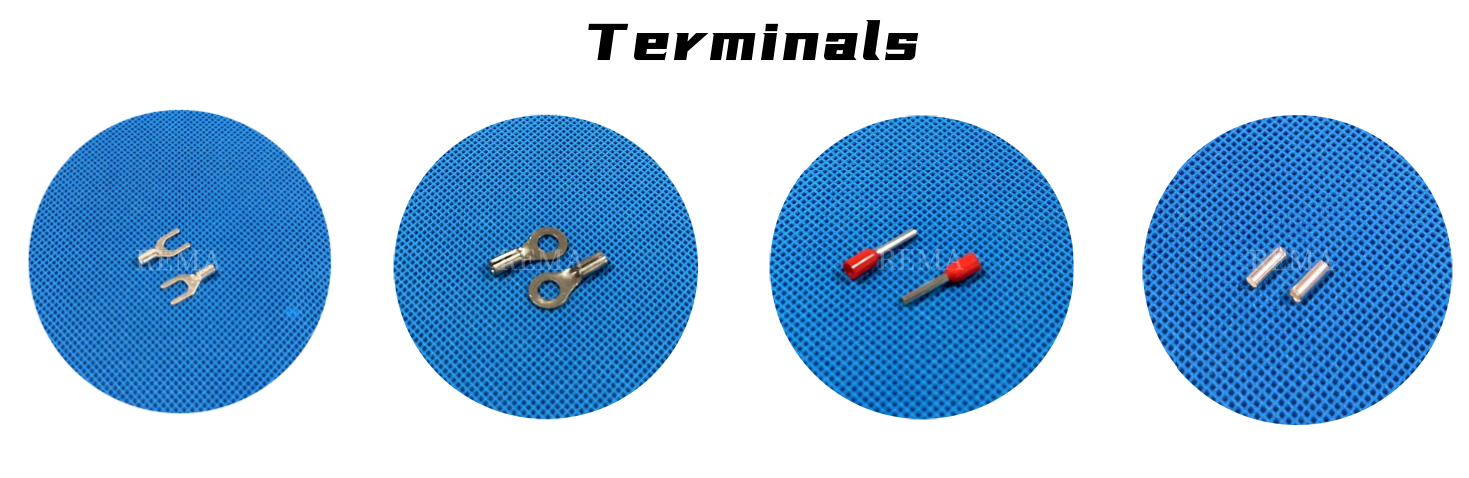

| 3.Total length: | **mm | 4.Wire length: | 500MM、..... |

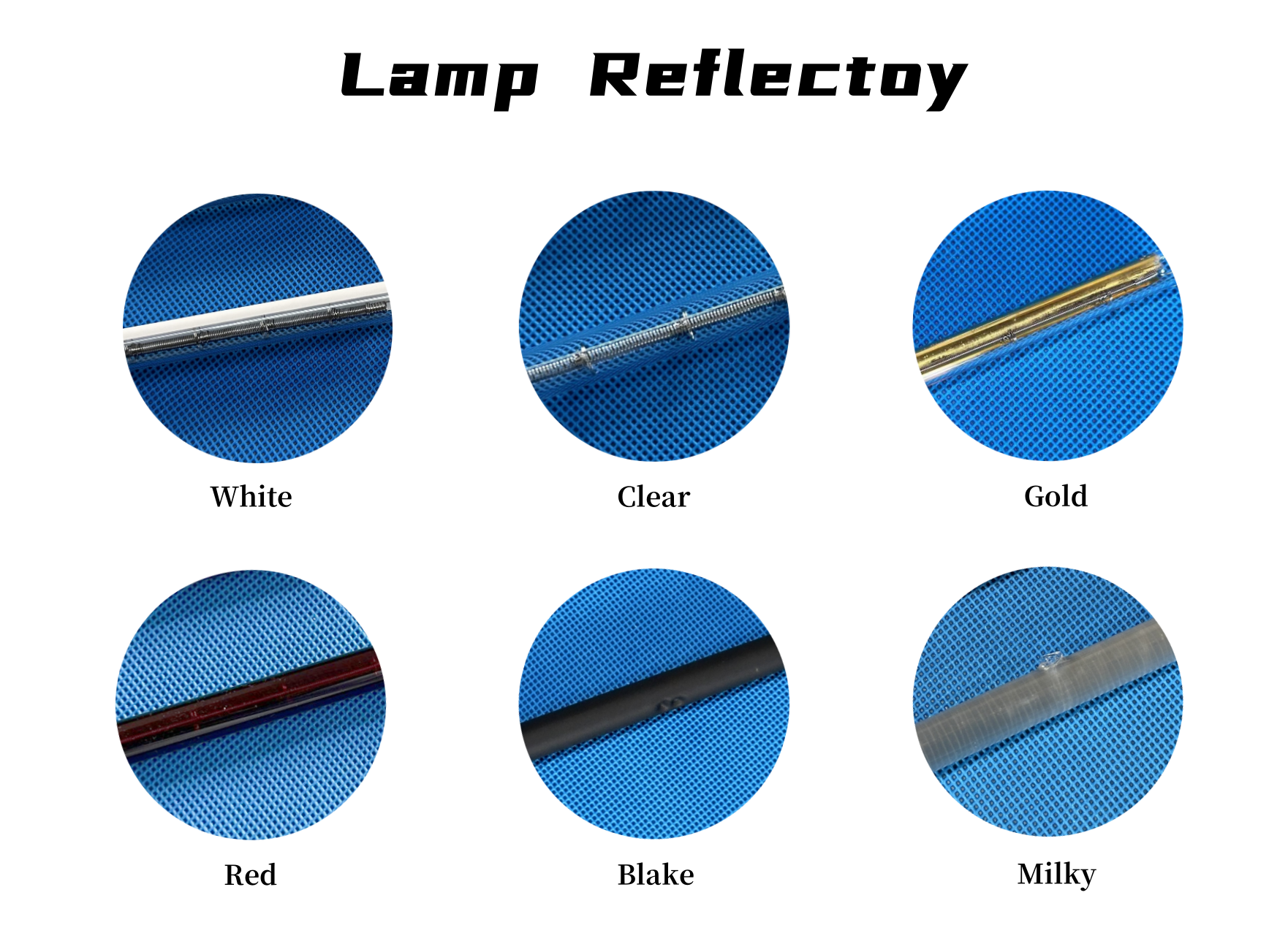

| 5.Coated or not.What color coating? | Gold/ White/ Clear/Black | 6.Base: | SK15、R7s、..... |

| Or you can directly send us the photos and drawings. | |||

Custom Lamp Base LOGO

REMA uses laser printing LOGO. Make the LOGO more clear , durable and not easy to disappear by friction.

AFTER-SALE GUARANTEE

ABOUT US

Elite team

Rema core members are experts in their respective fields, every staff working at his position at least 20 years, hold company as a warm family.

Quality leader

Rema leader, Mr. Wang , as a pioneer of innovative technology, participated in making and revising a number of national and industrial standard of infrared heating lamps and won a number of patents.

Cooperative learning

Rema have been maintain close contact and cooperation with major company at home and abroad, such as Chinese state-owned enterprise Lamplic and Toshiba, etc.

Technological innovation

REMA have been committed to infrared lamps production , quality improvement and Technological innovation, that keep REMA stand at the forefront of technology.

Winning

Base on reputation and efforts, REMA ODM /OEM for many factories, sells the infrared lamps to all the world and winning good reputation.